Design

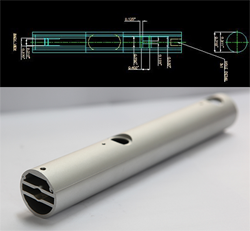

With an experienced staff of designers equipped with state-of-the-art software, MINICUT will accurately and promptly move your project through design into the tooling and production phase.

We use AutoCAD® networks, CNC-EDM and CNC Machining Centers to meet your goals, as well as your needs for pre-designed components of consistent quality and cost. The design team has the comprehensive experience in building and designing tools that optimize the manufacturing process. Our turnaround time and cost on proto sample build are extremely competitive in the industry. Our designers work directly with our tool makers to build tools that maximize part quality.

We have expertise in die casting, plastic injection, sheet metal fabrication designs; extensive knowledge in casting material and processes, resins and injection mold processes and design; design for cost and manufacturing by proper selection of material, fabrication process and mold design. We support customer's design with proper value analysis in the selection of material, processes, finishing and assembly technologies

Design for Manufacturability (DFM)

We make our partners competitive by providing design for manufacturability inputs to achieve price competitiveness.

MINICUT has experienced staff available to ensure that manufacturability issues are dealt with quickly and efficiently. This ensures our client's product launch dates will not be affected.

This can include, a critical to quality review for individual piece parts, assembly and/or the complete assembled product. It can also include a review of the BOM for component availability,

creation of test specifications and fixture design as required.

Material Selection

MINICUT established supply chain management and distribution channels, whom we have partnered with for years,

will provide quality materials exactly to our specifications at competitive prices. There are hundreds of commodity materials for mechanical and plastic manufacturing today.

Over the years, MINICUT Group manufacturers have helped clients select the best and most cost effective possible material for each product's application.

We also strictly complied with the standards and regulations enacted by relevant organizations for the procurement and use of raw materials, such as RoHS, REACH, Conflict-Free Minerals.

Quality Control

To ensure consistent quality MINICUT performs incoming inspection as well as out-going product inspection for every shipment before it leaves our manufacturing facilities.

This ensures that the product you receive will be the product you ordered without any unnecessary or unexpected delays.

Logistics

MINICUT manages and controls inventory purchases, confirms and expedites deliveries, stores inventory as required, delivers goods to the client's forwarding warehouse and provides import

and export documentation to support production builds and export of goods.

Buffer Stock for Just-in-Time (JIT) delivery:

MINICUT will stock and monitor pre-determined quantities of your products to ensure just-in-time delivery.

Post-Sales Service:

MINICUT provides swift RCA, RTV and RMA services to all products shipped. We have the established post-sales service processes for our customers around the globe.

Our turnkey approach to manufacturing insures you get the quality, price and delivery required without the problems of dealing with off-shore suppliers directly. We will design and build your tools and monitor your quality specifications throughout the manufacturing process.

Our turnkey approach to manufacturing insures you get the quality, price and delivery required without the problems of dealing with off-shore suppliers directly. We will design and build your tools and monitor your quality specifications throughout the manufacturing process.